The Role of Metal Casting in Progressing Production Technologies

Metal Casting have actually notably influenced the development of making technologies. They provide distinct layout versatility, enabling the creation of detailed geometries crucial for different applications. Modern spreading methods are being enhanced by innovations like 3D printing and automation. These growths not only boost effectiveness yet likewise address challenges in accuracy and sustainability. As industries proceed to evolve, the duty of Metal Casting continues to be crucial in forming their future. What exists in advance in this dynamic area?

The Development of Metal Casting Methods

As the demand for accuracy and performance in production has expanded, the advancement of Metal Casting techniques has actually gone through significant improvement. Historically, Metal Casting started with simple methods such as sand spreading and lost-wax spreading, which enabled artisans to develop detailed shapes. With time, developments in modern technology introduced processes like die casting and financial investment spreading, enhancing precision and reducing waste. Aluminum Foundry. The intro of computer-aided layout (CAD) and simulation software reinvented the preparation phases, enabling producers to expect potential concerns and optimize layouts prior to production. In addition, the advancement of brand-new materials, such as sophisticated alloys and composites, has actually widened the extent of applications for Metal Casting. Automation and robotics have more polished spreading processes, boosting uniformity and performance. Because of this, the Metal Casting sector has actually adapted to satisfy the requirements of contemporary manufacturing, focusing on sustainability and development to remain competitive in an ever-evolving industry

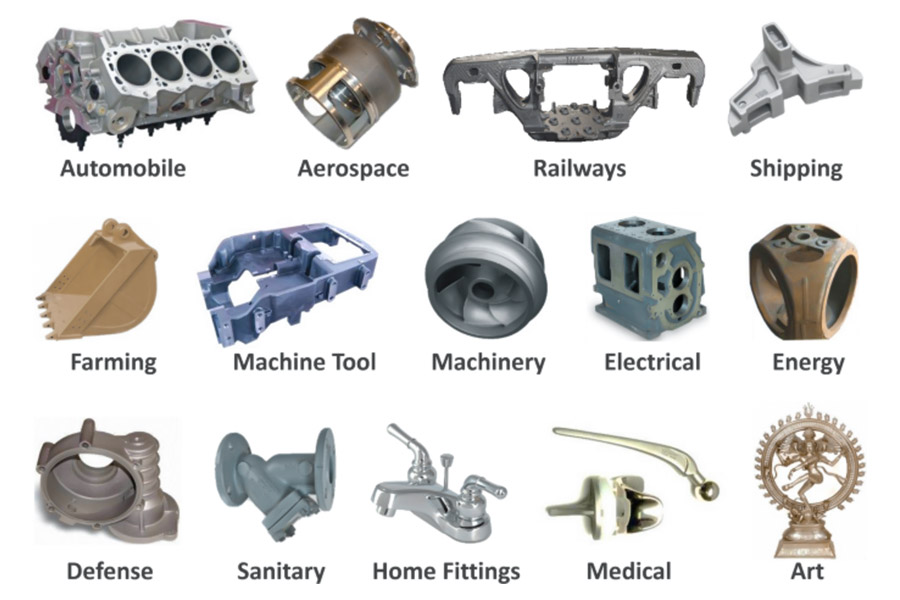

Applications of Metal Casting in Trick Industries

The advancements in Metal Casting techniques have opened up a broad range of applications throughout various sectors. In the automotive field, Metal Casting are integral for generating engine blocks, transmission real estates, and various other crucial components that require high toughness and durability. The aerospace sector uses spreadings for complex components like wind turbine blades and architectural components, making certain lightweight yet durable options for aircraft.

The building market utilizes Metal Casting for architectural components such as fittings and beam of lights, adding to the honesty of structures and facilities. In the power field, spreadings play a vital function in making elements for wind generators and power generation tools, boosting performance and integrity. On top of that, the clinical field take advantage of precision castings made use of in medical instruments and prosthetics, showing the adaptability of Metal Casting across varied applications. This broad use underscores the relevance of Metal Casting in modern manufacturing methods.

Benefits of Metal Casting in Modern Production

Metal Casting use many advantages that considerably boost modern-day production processes. One essential benefit is design adaptability; Metal Casting enables the production of complex forms and complex geometries that are impossible or commonly tough to achieve with various other manufacturing methods. This capacity enables producers to maximize item layouts for capability and performance.

Furthermore, Metal Casting can sustain a vast array of products, including light weight aluminum, iron, and steel, which can be tailored to fulfill details mechanical homes and deterioration resistance demands.

Cost-effectiveness is another notable benefit; Metal Casting procedures can create large quantities of get rid of very little material waste, thereby decreasing manufacturing expenses.

Additionally, the resilience of cast steel elements contributes to the longevity of items, reducing the need for frequent substitutes. In general, the advantages of Metal Casting considerably add to efficiency, sustainability, and advancement within modern production environments.

Innovations Driving the Future of Metal Casting

While conventional Metal Casting strategies have actually served the industry well for decades, current technologies are positioned to change the area. Developments such as 3D printing innovation permit fast prototyping and the manufacturing of complicated geometries that were formerly unattainable. These technologies not only enhance design versatility however additionally reduce waste and shorten lead visit homepage times. In addition, the combination of automation and robotics in casting processes is enhancing procedures, boosting accuracy, and boosting employee safety. Additionally, the growth of composite materials and new alloys is making it possible for the creation of more powerful, lighter spreadings customized for certain applications. Digital technologies, including expert system and artificial intelligence, are enhancing spreading specifications and predictive maintenance, driving better quality control. Collectively, these technologies are pushing the limits of Metal Casting, promoting better effectiveness and sustainability in production, and placing the market for future growth and competition.

Obstacles and Solutions in Metal Casting Processes

As advancements in Metal Casting modern technology remain to improve the industry, various obstacles remain that suppliers must deal with to totally utilize these innovations. One considerable concern is the irregularity in product homes, which can cause irregular top quality and efficiency. This irregularity frequently results from variations in raw products and processing conditions. In addition, this content the rising expenses of energy and products position economic constraints, pushing suppliers to seek much more effective procedures.

To fight these challenges, companies are progressively adopting automated systems and progressed simulation methods to improve precision and uniformity. Executing high quality control procedures throughout the manufacturing process additionally aids in spotting flaws early. Investing in research study for different materials may improve and decrease expenses sustainability. By resolving these challenges with ingenious services, the Metal Casting sector can improve efficiency and keep competition in the advancing production landscape.

Frequently Asked Inquiries

What Products Are Typically Utilized in Metal Casting Procedures?

Common products used in Metal Casting procedures include light weight aluminum, magnesium, iron, and bronze. Each material possesses special properties that cater to various applications, improving the convenience and performance of the final cast items in numerous sectors.

How Do Ecological Rules Effect Metal Casting Workflow?

Environmental policies urge Metal Casting procedures to take on cleaner techniques and technologies, usually boosting manufacturing expenses. Compliance might result in cutting-edge processes that minimize waste and discharges, inevitably advertising sustainability within the Metal Casting sector.

What Are the Precaution in Metal Casting Facilities?

Safety and security measures in Metal Casting her comment is here facilities consist of correct ventilation, individual protective devices, routine safety and security training, devices maintenance, and adherence to security regulations, making sure a safe environment for workers while lessening threats connected with unsafe products and processes.

Exactly How Is Quality Controlled in the Metal Casting Refine?

Quality assurance in Metal Casting involves extensive assessments, including aesthetic evaluations, dimensional checks, and material testing. Adherence to market criteria and carrying out high quality administration systems assures that castings fulfill specified needs throughout the manufacturing procedure.

What Is the Future Job Outlook for Metal Casting Professionals?

The future job expectation for Metal Casting experts appears encouraging, driven by developments in technology and raising need throughout different markets (Aluminum Foundry). Development in automation and sustainable practices will likely produce new opportunities in this field

Historically, Metal Casting began with easy methods such as sand spreading and lost-wax casting, which allowed craftsmens to produce detailed forms. Over time, innovations in modern technology introduced procedures like die casting and financial investment casting, boosting precision and minimizing waste. In enhancement, the medical field advantages from precision castings made use of in medical tools and prosthetics, demonstrating the versatility of Metal Casting across diverse applications. Metal Casting provide various benefits that substantially boost modern-day manufacturing procedures. Common materials used in Metal Casting processes include aluminum, magnesium, bronze, and iron.